BEIYAN LINE FOR COCOA BEAN TO CHOCOLATE BAR

The phrase "bean-to-bar chocolate" refers to the entire process of making chocolate, beginning with whole cocoa beans and finishing with a completed chocolate bar. As more and more small-scale chocolatiers embrace this technique, this artisanal method of creating chocolate is spreading around the world.

Cocoa Bean to Bar is the transformation and production process of chocolate starting from the raw cocoa bean to create single origin chocolate or different blends by artisan chocolate crafters controling all steps of transformation. The best artisan chocolatiers in the world are now using cocoa bean to bar line working from the pure cocoa bean to the finished chocolate product.

Master chocolatier can now create personalised chocolate as the final taste of the chocolate is not only dependent on the origin of the cocoa beans used but also on the way they are processed during the various production steps.

Understanding the different ingredients is one of the most important steps in making chocolate. When preparing bean-to-bar chocolate, it is crucial to choose and use the best cocoa beans, cocoa butter, sugar, milk powder, and other flavourings. Every ingredient is essential when making a chocolate recipe, and even small alterations can have a significant impact on the flavour, texture, and general quality of the chocolate.

COCOA BEANS

Cocoa beans are the heart and soul of chocolate making. They are made with the seeds of the Theobroma cacao tree, which grows in tropical regions around the world. Cocoa beans come in different varieties, each with its unique flavour and characteristics. The three primary varieties are Criollo, Forastero, and Trinitario. Criollo is known for its complex flavour profile and mild bitterness and is mostly grown in Central and South America. Forastero provides a strong chocolatey flavour with a hint of bitterness and is commonly grown in West Africa. Trinitario is a hybrid of Criollo and Forastero, providing a balance of both flavours and is grown in various locations around the world.

When selecting cocoa beans for bean-to-bar chocolate making, to ensure the best flavour and texture you need to look for beans that are plump, uniform in size, and free from any signs of mould or disease. The beans should have a deep, rich colour and a strong aroma. Using high-quality cocoa beans and nibs is essential in creating delicious and high-quality chocolate providing a rich, complex flavour and aroma to the chocolate.

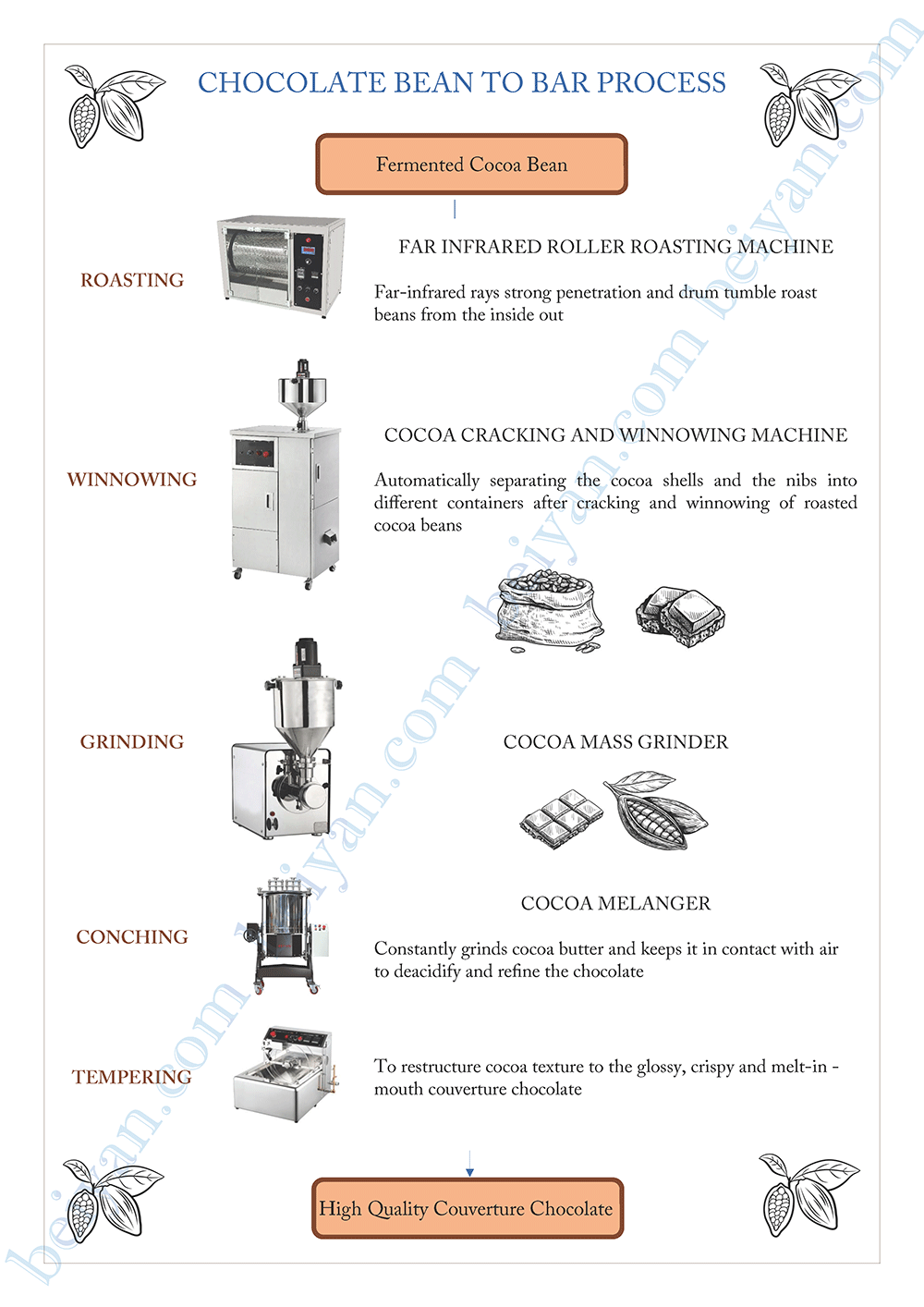

Roasting cocoa beans is a crucial step in chocolate making, as it helps to develop the beans' flavour and aroma. The roasting process involves heating the beans at a specific temperature for a specific period, depending on the desired flavour profile. Roasting time can vary from 10 minutes to an hour, and temperatures can range from 120 to 150 degrees Celcius. It is essential to monitor the roasting process closely to ensure that the beans do not burn, as this can affect the final taste and texture of the chocolate.

Discover our all in one offers to get the best result!

ARTISAN QUALITY BEAN TO BAR LINES

STARTER PACK (10-30 kg/day) : EUR 20,000

- Cocoa beans Roaster

- Cracker Winnover

- Liquor Grinder

- Melanger 10 kg

- Tempering Wheeling machine 15 kg

- Enrobing belt

STARTER LINE (30-60 kg/day) : EUR 65,000

- Cocoa beans Roaster

- Cracker Winnover

- Liquor Grinder

- 2 Melangers 20 kg

- 1 Chocolate tank 50L

- Cocoa butter press and powder grinders

- Tempering machine with Enrobing belt

- Moulding and cooling tunnel 6 m